how many penetrator sizes does a brinell hardness tester have|brinell hardness tester manual : purchasers The ball size is most commonly 10mm, but 5 mm, and 2.5mm can also used. Most commonly the a Brinell tester is setup to test at 3000 kg, but other loads of 187.5, 250, 500, 750, 1000, and . Resultado da Previsão para 15 dias Maceió - AL. Gráficos. 26 seg. 25°. 32°. 90%. A previsão do tempo para segunda-feira é de Sol com algumas nuvens. Chove rápido durante o dia e à noite. Madrugada.

{plog:ftitle_list}

webLe plus grand évènement scout de Wallonie ! Découvre notre site sans plus attendre. La Scout Silver Cup se déroulera le 16 mars 2024 Inscriptions le 11 novembre prochain !

The ball size is most commonly 10mm, but 5 mm, and 2.5mm can also used. Most commonly the a Brinell tester is setup to test at 3000 kg, but other loads of 187.5, 250, 500, 750, 1000, and .A Rockwell C scale test on hardened steel, for example, penetrates to a depth of approximately 0.0035 inch, with the diameter of the indentation only 0.019 inch, which is barely visible. The .

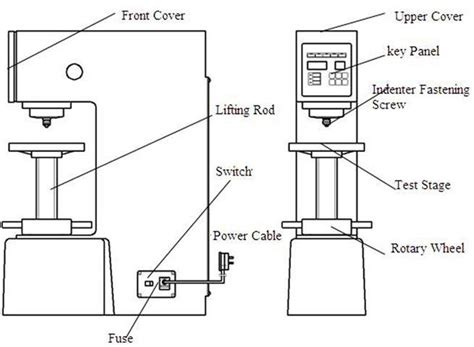

The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y axis) of the indentation are measured, and the hardness value is .The Brinell hardness test is a widely recognized method for determining the hardness of various materials. It involves applying a constant load or force, typically ranging from 187.5 to .The Brinell tester commonly consists of a vertically mounted hydraulic cylinder, which is used to force a ball into the surface of the metal to be tested. For steel applications, the ball is 10 mm (0.394 in) in diameter, the force applied is 3000 .Standard Brinell hardness test: In this test, a load of 500 to 3000 kg is applied to the surface of the material for 10 to 30 seconds, depending on the hardness of the material. Micro Brinell hardness test: In this test, a load of less than 1 kg is .

According to ISO 6506, the spherical indenter made of hard metal (tungsten carbide) is pressed into a specimen (workpiece) with a defined test load (between 1 kgf and 3000 kgf) to determine the Brinell hardness (HBW).

Though loads of 500, 1000, 1500, 2000, 2500, and 3000 N are available in a typical Brinell hardness tester, a load of 500 N is used for testing relatively soft metals such as copper and .

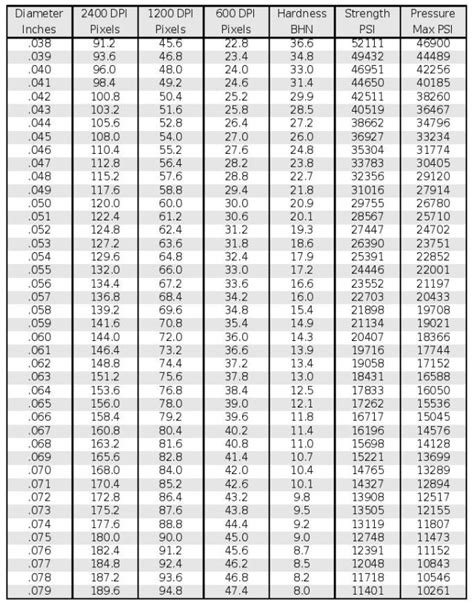

The Brinell hardness number is designated by the most commonly used test standards (ASTM E10-14[2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide).The typical relationship between indentation diameter and HB is provided in Table 2.The standard ball for Brinell testing is 10 mm (±0.005 mm) in diameter and should have a minimum hardness of 850 HV.When balls of smaller size are used, the load as well as the ball size should be specified along with the test result.The Brinell hardness value is designated by the letters HB (Hardness Brinell) Figure 1 illustrates a typical Brinell hardness tester. Figure1, The Brinell Hardness tester in action. Figure 2 shows the schematic of the actual .

As with most things, one size does not fit all, so to speak, which is basically why there are many different variations of hardness test methods like Vickers, Brinell, and Leeb impact. The most commonly used hardness test method is the Rockwell hardness test. This is largely due to the ease of use and that the result is read directly from the . Because the indentation ball is so much larger than in other testing methods, hardness values derived from the test provide a more representative average hardness of the part. More information about Brinell testing can be found in ASTM E10.

Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . 3000 – Load size kgf; 30 – Load holding time s; General conditions: 10mm steel ball diameter; 3000kg load; 10s pressure holding time, namely HB280 . Selection Table of Brinell Hardness Test P/D 2 .

The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number. Brinell hardness of some materials. Material. Brinell Hardness. Copper. 35 HB. Aluminum (pure) 15 HB. AW-6060 aluminum.The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.

The Telebrineller Brinell Hardness Testing System stands out as the best QA solution for ensuring top-notch hardness testing quality.. . or one standard Rockwell hardness number, corresponds to the vertical movement of the penetrator (0.000080 inches) A vertical shift of 40 millionths of an inch is represented by one apparent Rockwell number .In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves a pyramid-shaped indenter being pressed into a specimen, the Brinell method uses a spherical indenter.

3.2. Brinell Hardness Test. . Vickers hardness is a measure of the hardness of a material, calculated from the size of an impression produced under load by a pyramid-shaped diamond indenter. Devised in the 1920s by engineers at Vickers, Ltd., in the United Kingdom, the diamond pyramid hardness test, as it also became known, permitted the . In the original test proposed by Brinell, the load L is expressed in kilogram force. If L is measured in N (SI system), Eq. 1 should be divided by 9.8065. The full test load is applied for a period of 10–15 s. Two diameters of impression at right angles are measured (usually in the range 2–6 mm), and the mean diameter value is used for calculating the Brinell hardness .

lee brinell hardness tester chart

In metallurgy: Testing mechanical properties .oldest of such tests, the Brinell hardness test, uses a 10-millimetre-diameter ball and a 3,000-kilogram load. Brinell hardness values correlate well with UTS.Standard Brinell hardness test: In this test, a load of 500 to 3000 kg is applied to the surface of the material for 10 to 30 seconds, depending on the hardness of the material. Micro Brinell hardness test: In this test, a load of less than 1 kg is applied to the surface of the material for a longer duration, typically 15 to 60 seconds.The STE Pin Brinell testers are the first Brinell hardness testers at a low price. The unique impact hardness method uses a shear pin to control the force applied by a hammer, so it significantly reduces the costs of getting started in Brinell .Hardness tests of metals are essential to manufacture reliable big machines and automobiles. The hardness test should be first selected according to the needs of the material. You can find answers to questions about the Brinell and Rockwell in the article, as we have clarified the difference between the two tests.

Indenters for the Brinell hardness test shall be tungsten carbide balls of four allowed diameters (1, 2.5, 5 and 10 mm). Dust, dirt, or other foreign materials shall not be allowed to accumulate on the indenter, as this will affect the test results. Portable Brinell hardness testing machine Brinell Hardness Tester: This tester best serves materials that are rougher in texture. The diameter of the resulting indentation after a hardened steel or carbide ball has been pressed into a surface at a given load might be measured to evaluate its hardness. The Brinell hardness test is a commonly used hardness testing method that measures the hardness of materials. Home; Products. Special Offers. . The force applied ranges from 500 to 3000 kgf, depending on the material being tested and the indenter’s size. The test procedure begins by applying a load to the material for a specified period .The Brinell hardness test (HBW) serves as a crucial scale for quantifying material hardness, defined in ASTM E10 and BS EN ISO 6506-1 standards. . Rockwell’s method does not measure the size of the imprint, but the depth of the indentation. This measurement is then converted to a Rockwell hardness value directly on the machine.

How to Use a Rockwell Testing Machine. Pick out the penetrator. Usually soft materials like 1018 mild steel will use the Rockwell B scale, which makes use of a 1/16″ rounded steel penetrator with a 100 Kg major load. . Brinell Hardness Test. You might have heard about this in school, that you can get a ball bearing, whack it with a hammer .The typical relationship between indentation diameter and HB is provided in Table 2.The standard ball for Brinell testing is 10 mm (±0.005 mm) in diameter and should have a minimum hardness of 850 HV.When balls of smaller size are used, the load as well as the ball size should be specified along with the test result. Brinell Indentation Diagram. In the standard method of the Brinell Hardness Test, we use 250 to 500 kg of load for soft material and 500 to 3000 kg of load for hard material such as steel and iron.

multilayer thickness measurement

The Brinell hardness test is a standardized test used for measuring the hardness of metals and other hard materials. Do not know how to perform a Brinell Hardness test? This is an article to teach you detailed Brinell Hardness tests procedure on various materials. + 86 755 61301520; [email protected]; Search. Home;See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload .The Brinell hardness test records the diameter and depth of the indentation caused by a ball-shaped indenter, with the indenter pressed into a material's surface. This is the guide on how to read and represent brinell hardness values. + 86 755 61301520; [email protected]; Search. Home; About Us. Who We Are;

Brinell hardness testing methods are defined in the following standards: ASTM E10 and ISO 6506. Skip to content +1 847-295-6500; [email protected]; Mon - Fri: 8am - 4pm CST; About Contact Products Close . Due to the wide number of ball sizes and loads available, it is possible to test a very wide range of hardness values using the Brinell .

multiple beam interferometer thickness measurement

1 de nov. de 2023 · O Centro de Atenção ao Cidadão (CAC) (foto) da f12bet mines deesportes da sorte mines , continua recebendo a documentação que ficou pendente durante a semana de mutirão da COHAB. Os mutuários que não participaram do mutirão na semana passada vão poder ir até o CAC para sanar as dúvidas que por ventura venham .

how many penetrator sizes does a brinell hardness tester have|brinell hardness tester manual